Bob, Glenn, and Dan's Grand Distillery Tour

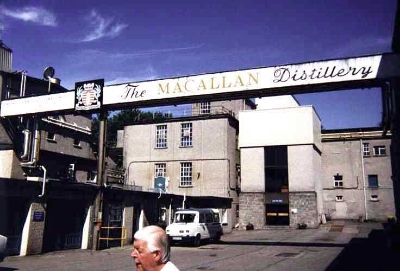

We got up bright and early, and had a full English breakfast before heading out to the Macallan distillery for our first tour of the day. After being ushered into the waiting presentation room, we saw a cute little animated movie explaining how scotch whisky is made. This was followed by a lecture, which reinforced the points of the movie. As it turns out, each of the lectures we would receive began with the same line, which needs to be delivered in a thick Scottish accent for full effect:

“There are three ingredients in Scotch: Barley, Water, and Yeast!”

This would become our mantra—not only for the two day tour, but perhaps for the rest of our lives.

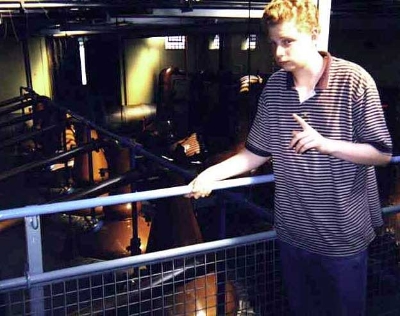

All the tours basically operated the same way. They would lead you through the process of making the whisky and then end up in a tasting room.We eventually toured six distilleries: The Macallan, Glenifddich. Strathisla, Glenfarclas, The Glenlivet, Glen Grant. None of the distilleries were in full production, and most were taking the summer off to perform maintenance on the equipment. Of the four tours we went on, The Macallan was by far the best. The tour itself was approximately 2 hours and it covered the complete making of whisky from the malting of the barley to the bottling of the spirit. There was no active processing going on at the time, but subsequent tours filled in those blanks. Below is a pictographic tour showing the various steps in the whisky making process. To track our progress through the Speyside region through the eyes of our youngest member, Danny, see the gallery below.

Malt grinder

The first step is the barley. The barley gets soaked in water for a couple of days in order to promote germination and therefore change starch in maltose (a sugar). The barley is then dried over kilns that are fueled, at least in part, by peat. The amount of peat used in the drying process varies from region to region and from distillery to distillery and has a profound impact on the flavor of the whisky. Virtually no distilleries process their own grain nowadays, but outsource this function to others who will follow their exact recipes.

The malted barley arrives as the distillery, is placed into large hoppers and then crushed in the large mill (left) where the stones are separated from the grain. This milled barley (grist) is then sent to a large mash tun (below right) where it is mixes with 3 washes of water at progressively higher temperatures. The purpose of this is to extact the sugar from the malted barley. This sugared water is called the wort and the remaining grist is called draft, which is used as animal feed.

Mash Tun

The wort is then allowed to cool and is pumped into a washback (below left) where yeast is added and fermentation is allowed to take place. These are massive tanks that have huge stirring bars in the middle to keep everything moving. They also have to be located in such a way that the carbon dioxide has a place to escape without suffocating the workers.

The wash from these tanks is then pumped to the stills where two sets of distillations take place.

Washback (or Wash Tun)

Stills

Only the middle cut of each distillation run is used, thus discarding the early and late portions of the distillation that contain contaminants. This selections process takes place using a safe (below). The shape of the stills are apparently quite important to the ultimate taste of the whisky. Each distillery had it's own peculiar stills shapes (left).

Distillation Safe

Following the two distillations, the spirit (70% alcohol) is then pumped out of the building and placed into wooden casks for aging. There are essentially two types of casks that are currently being used. Most distilleries use American oak casks in which bourbon had be previously aged. The alternative are casks used in the production of port. The Macallan uses almost exclusively sherry wood, while Glenlivet, for example, uses mostly American oak (below right).

Oak casks

After three years in cask, the spirit can officially be called whisky, but single malts age for much longer. After aging is completed, samples are taken from up to 100 casks and brought to the nosing room (below). There, the chief noser will determine the blend of the casks that will match the distilleries previous outputs in terms of taste, color, and smell. Having “the nose” is a real gift, and only few people in 100 have it. In order for a blend to pass muster, it must first pass the test of four other “noses.”

After passing the test, spring water is added to the casks used in the final blend to bring the alcohol level down to 40%. Once in the bottle, the whisky will not change flavor.

The Nosing room, where the blending happens

OK. So that's how whisky gets made. Now, onto:

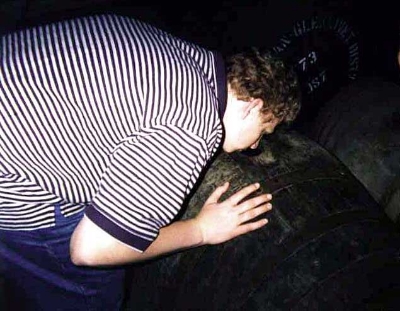

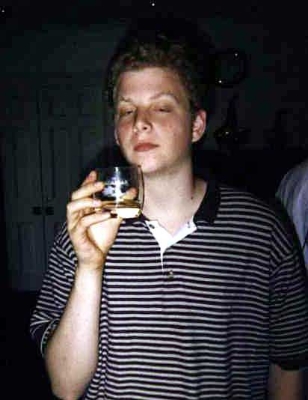

Danny's Excellent Whisky Adventure